Solution Overview

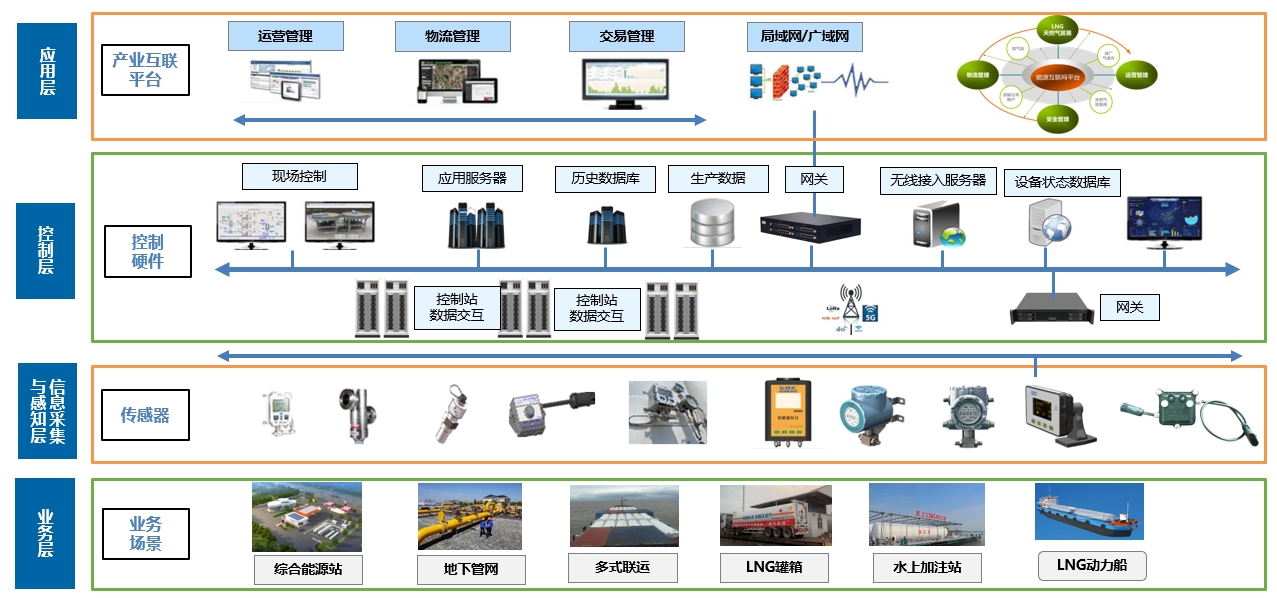

China's first end-to-end system integrating digital intelligence technology with energy full-scenario applications, independently developed by AJH

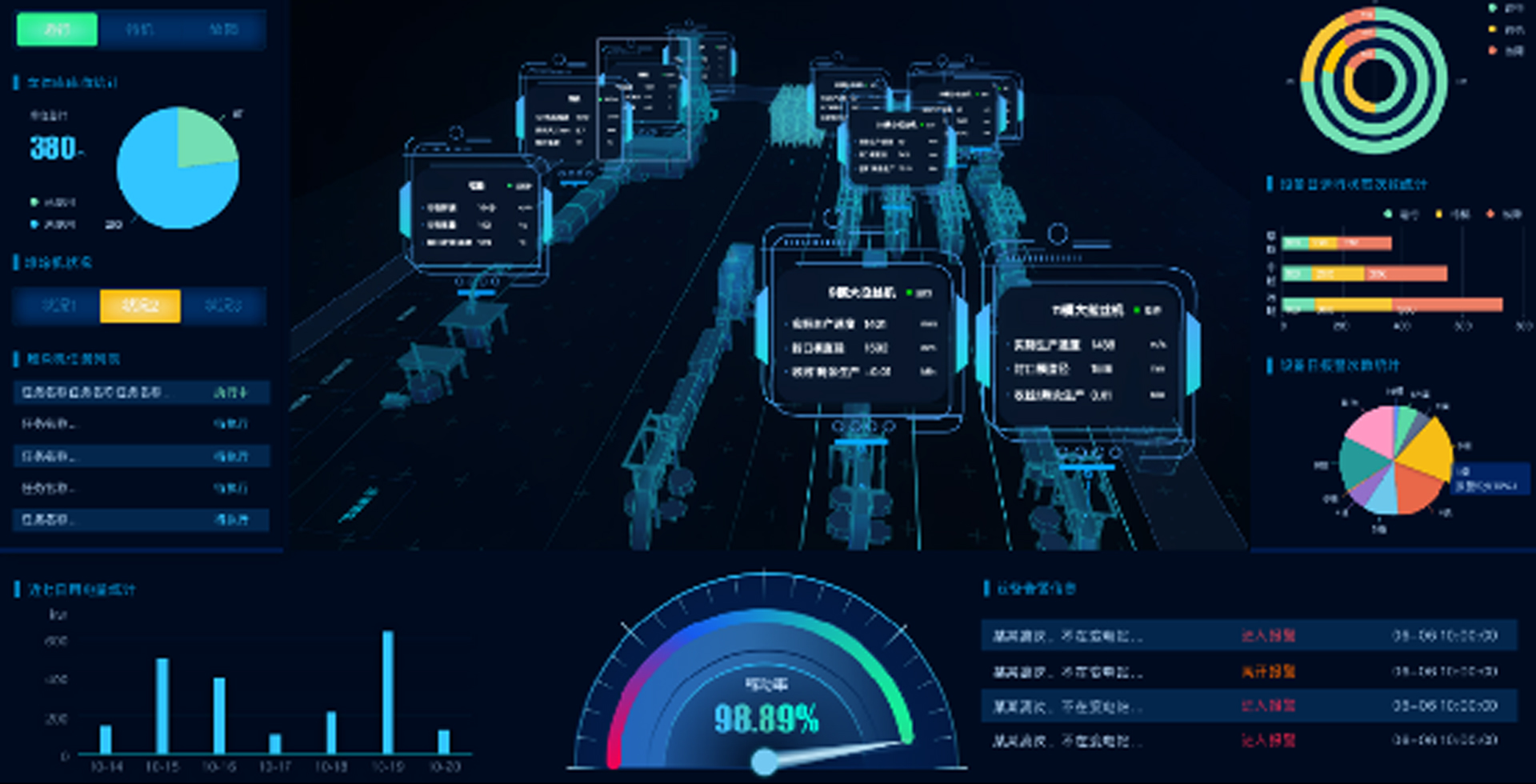

As a key emission reduction industry, the steel industry faces challenges of high energy consumption and large emissions. AJH has developed China's leading full-scenario digital intelligence solution for steel enterprises' coke oven gas resources, combining advanced PSA pressure swing adsorption technology and deep-cooling liquefaction processes with intelligent IoT and data analysis technologies to achieve joint production and efficient management of hydrogen and LNG.

This solution has been successfully applied to the Angang Zhongji project, with an investment of approximately 600 million yuan, processing 438 million cubic meters of coke oven gas annually, producing approximately 100,000 tons of LNG and 24 million cubic meters of hydrogen annually, reducing carbon emissions by approximately 470,000 tons per year, providing a successful model for promoting green and low-carbon transformation of the steel industry.